Let’s Talk About PVC Profile Extrusion

Understanding the Process

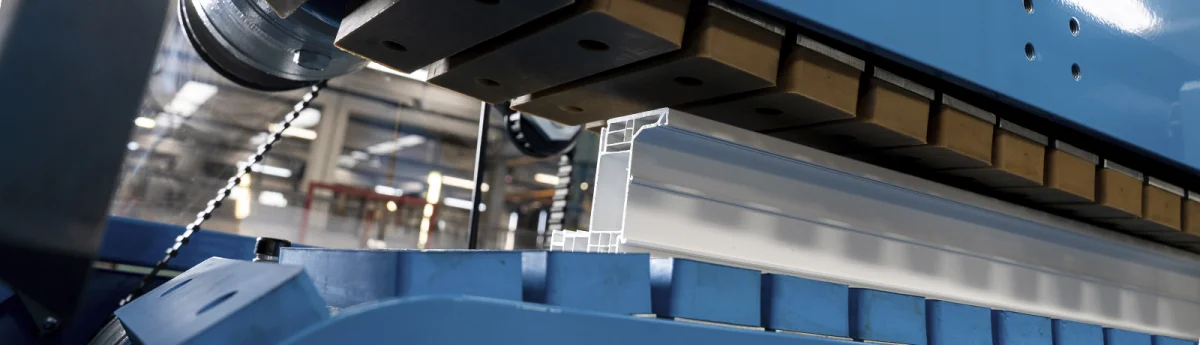

PVC profile extrusion is a cornerstone technology in plastics processing, widely adopted in construction, automotive, electrical, and furnishing industries. The process involves transforming PVC resin—typically compounded with stabilizers, lubricants, pigments, and functional additives—into precise profiles through controlled melting, shaping, cooling, and cutting. Inside the extruder, a screw conveys the compound through a sequence of heating zones where it is plastified and homogenized. The molten PVC is then forced through a die engineered to define the geometry of the profile. Once extruded, the material enters calibration and cooling units that stabilize its dimensions and prevent deformation. Finally, the profiles are cut to length and subjected to quality checks to ensure both dimensional accuracy and surface finish. This continuous method delivers efficiency, repeatability, and design flexibility, enabling manufacturers to produce complex cross-sections, co-extruded parts, and customized textures on an industrial scale.

Technical Challenges in PVC Profile Extrusion

Despite its advantages, PVC extrusion comes with inherent challenges that demand technical expertise and process discipline.

Surface Defects and Melt Instabilities

Profiles may show imperfections such as melt fracture, sharkskin, or die lines. These are typically linked to excessive shear stress, poor die design, or contamination on flow surfaces. Beyond aesthetics, such issues often indicate deeper problems in melt rheology and equipment wear.

Voids, Air Traps, and Structural Weaknesses

Moisture in the raw PVC or insufficient venting can lead to bubbles and voids within the profile, reducing mechanical performance and durability. Inconsistent mixing can also cause local variations in density or weaknesses in the extrudate.

Dimensional Inaccuracy, Warping, and Bowing

Maintaining dimensional tolerances is one of the most persistent challenges. Warping often arises from uneven cooling, surging output due to screw wear, or unstable temperature profiles. This not only affects product conformity but can also create difficulties in downstream assembly or installation.

Degradation and Discoloration

PVC is heat-sensitive. When exposed to excessive residence times or hot spots in the die, it can degrade, causing yellowing, black streaks, or even embrittlement of the material. Sub-optimal stabilizer systems or dead zones in the die exacerbate this phenomenon.

Flow Imbalances and Die-Related

Distortions Complex geometries—especially hollow or asymmetric profiles—pose risks of uneven melt distribution, die swell, or localized stress concentrations. Without compensation in die engineering and careful balancing of flow, the result is distortion or inconsistent wall thickness.

Strategies for Process Optimization

Managing these challenges requires an integrated approach, combining robust machinery, advanced process control, and careful material handling.

1. Precision in Material Preparation: a homogeneous compound is the foundation of quality extrusion. Controlled dosing of additives, efficient mixing, and proper drying of resin are essential to avoid voids, discoloration, or mechanical weaknesses. Using stabilizer systems tailored to the application helps maintain melt stability even at demanding processing conditions.

2. Thermal and Process Stability: consistent temperature control across the barrel, screw, and die ensures uniform plastification and avoids localized overheating. Screw speed and back pressure must be balanced to prevent surging or melt fracture. Continuous monitoring of melt temperature and pressure provides valuable data for fine adjustments.

3. Advanced Die Design and Maintenance: modern die engineering compensates for die swell and ensures balanced flow across complex geometries. Regular cleaning and inspection prevent buildup and surface damage that could lead to streaks or flow disturbances. Modular die systems can also shorten setup times and enhance flexibility.

4. Optimized Cooling and Calibration: uniform cooling is crucial to dimensional stability. Water baths or air cooling systems should be designed to deliver consistent thermal transfer across the profile. Closed-loop cooling solutions further enhance energy efficiency and process repeatability. Proper calibration, with vacuum sizing plates or calibrators, ensures profiles retain their shape and meet strict tolerances.

5. In-Line Monitoring and Quality Control Integrating in-line sensors for dimensions, surface quality, or melt pressure allows deviations to be detected in real time. Automated feedback systems can adjust puller speed, screw rpm, or cooling conditions instantly, reducing scrap and ensuring batch consistency.

6. Operator Expertise and Preventive Maintenance: even the most advanced extrusion line requires skilled operators and proactive maintenance routines. Training and process know-how are key to identifying early signs of instability, while preventive interventions on screws, barrels, and dies safeguard long-term performance.

Final Considerations

PVC profile extrusion remains one of the most versatile and efficient plastics processing technologies. However, the difference between standard production and best-in-class output lies in process optimization: precise compounding, thermal stability, intelligent die engineering, and robust in-line control systems. At Tecno System, we design and deliver extrusion lines engineered to overcome these challenges. Our solutions combine high productivity, reliability, and advanced automation to support manufacturers in achieving superior quality at scale.

Get in touch with our team to discover how we can optimize your extrusion process and develop a tailored solution for your production goals.